The Masher

Blaggers Guide To Bleeding Air From A Diesel Engine

Squall 14, Autumn 1996, pg. 43.

Diesel engines are very simple and reliable but they need a good clean supply of fuel to work. If you run your vehicle with too little fuel in the tank air gets into the fuel lines and the engine will die. A leaking fuel line, dirt causing a blockage or changing a filter all let air into the lines. To start the engine again you will need to bleed the air out of the system completely.

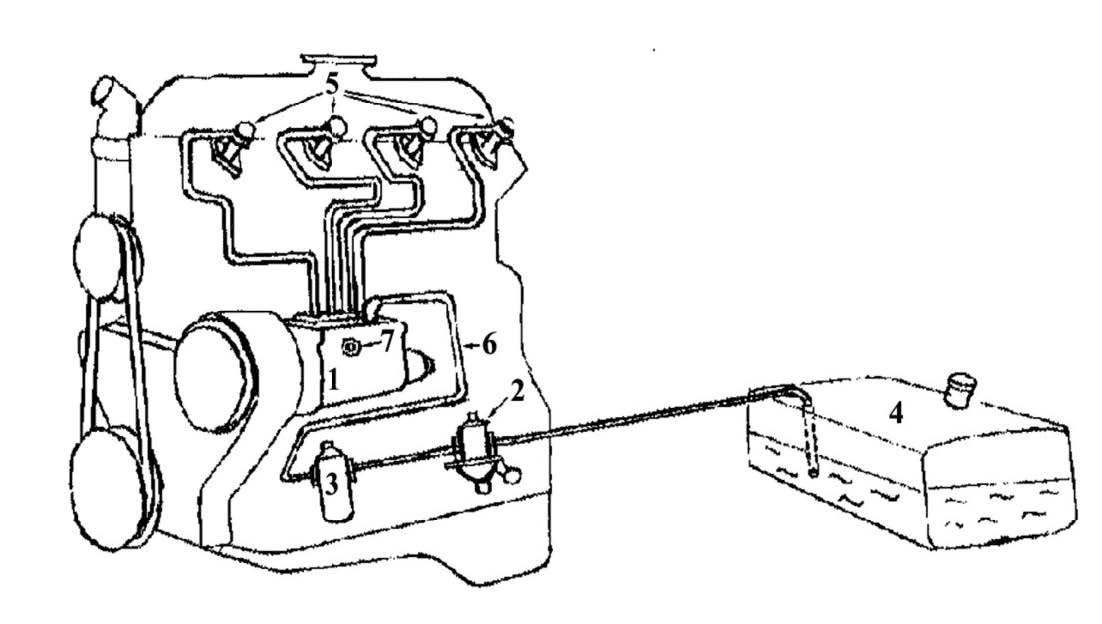

The first thing to do if you think there’s air in the system is to stop trying to start your vehicle with the starter motor. Save the batteries for later - you will need them. If you’ve run out of fuel put at least a couple of gallons at least in the tank. Then find the injector pump (1), fuel lift pump (2) and filter (3) on the engine body. The fuel lift pump has a small lever on the side by which you can hand pump fuel through the system and drive the air out.

The fuel pipe goes from the tank (4) to the lift pump, to the filter into the injector pump then splits into four (or six for a six cylinder) to take fuel to each injector (5).

To begin bleeding the air out slightly loosen the fuel line (6) on the injector pump side of the filter body. Pump the lever on the lift pump regularly (every 2-3 seconds) until fuel starts to leak from the loosened connection. If after 2-3 minutes nothing comes out turn the engine a 1/2 turn and try again. When you get a reasonable spurt of fuel with out any air bubbles on each down stroke of the pump tighten the connector.

Next find the bleed valve (7) on the body of the injector pump - it will probably be a nut going into a bolt on the side of the casing. Again loosen it slightly and pump the lever on the lift pump until a good spurt of bubble free fuel leaks out on every down stroke - tighten the bleed valve. Finally loosen the fuel pipe connectors to all your injectors by a half turn, turn the engine over with the starter motor for about five seconds. All of the loosened pipes should have leaked fuel. If not repeat the procedure of bleeding the injector pump and try again.

When you see fuel leak from all the pipes gently tighten the connections and if all else is well your vehicle will start. Run the engine until warm and check for fuel leakage from any of the connections you have undone. All the connections in fuel systems are brass - very soft and easy to misthread. Take great care not to over-tighten or they will break.

If you get air in the system every time you drive the vehicle and you know there is sufficient fuel in the tank then there must be a leaking connection between the fuel tank and the lift pump. Plumbers’ gas fitting tape is the cheapest and easiest way to mend leaking connectors. Wrap 2 or 3 turns around the male side of a connection when you refit the fuel pipe.

Back to The Masher main page click here